Lessons learned from Ford's assembly line

The influence of innovation.

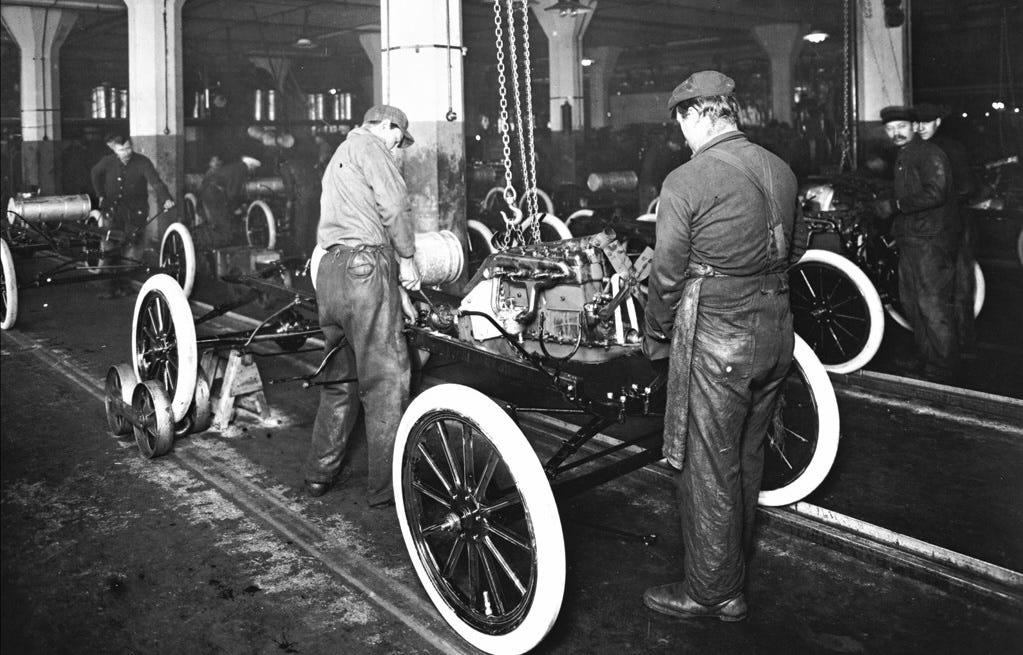

On this day in 1914: Ford introduced its assembly line for the Model T.

It helped Henry Ford achieve his goal to “democratize the automobile.”

The Model T had first been introduced in 1908. At an initial price of $850, it was roughly 40% of the cost to buy an average car at the time.

Ford successfully sold more than 6,000 Model T’s in the first year.

But that price was still about $28,000 in today’s prices.

And Henry Ford wanted to make much more progress. “When I'm through, everybody will be able to afford one, and about everybody will have one,” Ford said in 1909.

Ford would implement lessons learned during a visit to a meat packing plant in Chicago. 3,000 Model T parts would be assembled in 84 distinct steps, performed by workers along the line.

The drop in assembly time was astonishing.

Completing a Model T now took 90 minutes, down from 12 hours. Eventually, a car would roll off the line every 24 seconds.

Over time, the price of a Model T dropped from $850 to less than $300. And Ford’s market share grew from roughly 9% in 1908 to 48% in 1914. By 1921, it had surged to more than 60%.

Of course, the success of Ford’s assembly line also required a highly efficient workforce.

And in 1914, at the same time that the assembly line was being introduced, Henry Ford took the radical step of introducing a $5 a day minimum wage for his employees. That was more than double the average factory wage at the time. Ford hoped the headline-making move would reduce the amount of employee turnover. But it would also enable his own employees to participate in the automobile dream. The average assembly line worker at Ford could purchase a Model T with four months’ pay.

By 1927, Ford had sold more than 15 million Model T’s, making it one of the most successful vehicles of all-time… and perhaps, the most influential.